John Deere & Co.

Click for PDF version of John Deere & Charles Deere -- John Deere & Co. -- Biography

Click for John and Charles Deere - Wikipedia page

Introduction

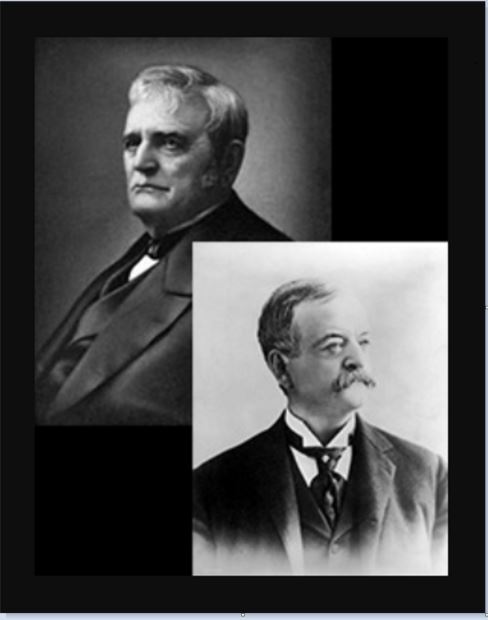

John and Charles Deere

Charles Deere (1837-1907) began working in his father’s firm at the age of sixteen in 1854 (104). He was a recent graduate of Bell’s Commercial College in Chicago where he learned bookkeeping, commercial law, business math, and the art of detecting counterfeit bills. (104) It was bookkeeping that his father John Deere (1804-1886) was especially interested in seeing Charles learn. Bookkeeping and other financial aspects of business were a mystery to John and this disability almost sank the plow manufacturer more than once (97, 125). In Charles, John had a family member he could trust implicitly and who was better educated. This freed John to do what he did best, innovating and marketing.Charles quickly developed an understanding of the company’s books and established family control over internal finance. Having accomplished this he turned to selling, shortly becoming the head of sales (104). In 1857 Charles Deere, became a partner in a newly formed partnership called John Deere & Co (125). This partnership accomplished three things. First, it assigned an ownership interest in the company to Charles for the first time (twenty five per cent). Second, it shifted as much cash as possible out of the company and into the hands of John and Charles Deere. Finally, it established Charles Deere as the principle manager of the company, while removing John as principle manager (126-127). Charles was barely 21 (or possibly 20) and may not have been completely prepared for this elevation, but external circumstances forced the reorganization. In order to understand Charles Deere, his early ascension, and his influence on the John Deere Company it is necessary to begin with John Deere and the company’s emergence. JOHN DEERE Somber events forged the beginnings of John Deere & Company. In 1808 William Deere, John’s father, was lost at sea leaving his widow with four sons, two daughters, and some heavy debts (7). These hard circumstances must have had an impact on the character and drive of John Deere. They certainly limited his education. Between 1825 and 1829 John, trained as a blacksmith, worked for several different Vermont businesses in his trade (12). In 1829 John opened his first blacksmith shop which failed (13). Deere moved to Royalton, worked for someone else for awhile; moved again to Hancock and opened a new smithy which also mired him in debt (27). The prospect was financial ruin and debtor’s disgrace in 1835. ALONG THE FRONTIER A somber event also occurred in Western Illinois in 1832. Black Hawk, chief of the Sauk and Fox Indians, frustrated with immigrant incursions on Indian treaty land and chafing over treaty terms, led approximately 1000 Indians in an uprising (Compton’s, 1995). Although a newspaper sensation, a militia of Illinois citizens had little difficulty in the several actions of the “Black Hawk War,” which largely consisted of chasing the Indians from place to place. Finally, at the mouth of the Bad Axe river in Wisconsin, the Indians were annihilated and Black Hawk captured (Bookshelf, 1994). The Black Hawk War effectively ended the Indian peril in Western Illinois and opened up the area to immigration. In particular, it established the relative safety of settlers in both the Grand Detour, Illinois and the Moline, Illinois areas – – sites of future John Deere businesses. The publicity also served to draw more immigrants to the area (74-75). In 1836 John Deere left Hancock, Vermont for Grand Detour, Illinois. Founded in 1835 on a bend of the Rock River in Western Illinois, the site was chosen because it afforded the ability to make use of the river’s power. Deere left his pregnant wife, a son (Francis Deere, born 1828), and three daughters and took only the tools of his trade to begin again in a wilderness (29). GRAND DETOUR Grand Detour lies on a bend of the Rock River where, according to Indian legend, it found itself so beautiful it had to turn around to look at itself (27). While the terrain was beautiful when John immigrated in 1836, the town was primitive and had not greatly improved by 1838 when his family joined him (Charles Deere was born in 1837). One traveler, in 1839, kept awake all night by the smells in his room and the howling of Grand Detour wolves, provided a detailed description of the poor food and lodging he received there, then stated: “8 a.m. Jumped into stage with a light heart & belly too…shall long remember Grand De Tour – shall hold it up in warning to all travelers.”(58) While primitive, the community was nevertheless growing and thriving. New people were moving in regularly and everyone was involved in constructing a home, a business or a farm. The national economy was dismal as a result of the Panic of 1837, but Grand Detour was not plugged into the economy yet, and boomed with the influx of people and their capital which often represented their life savings. On a day-to-day basis capital wasn’t needed anyway, as a system of barter was in full effect (56). Grand Detour and other similar settlements grew in part because of the poor economic times, forcing many people out of the depressed East and into places where cash was not critical for trade. Still, by 1842 the two general stores had decided on a cash only policy as evidenced by their advertisements in the short-lived Rock River Register. The Brick Store, after listing numerous items available for sale, closed with the comment: “No credit will be given, NONE NEED INQUIRE” (61). The other general store owner stated in advertisements that he would sell “…at the best cash prices.” The barter system was still available otherwise, however, as the shoemakers, Palmer and Eddy, would take wheat. The cabinet maker would take lumber or wheat (61). This provides a brief overview of the economy and society in which John Deere made his real start. THE STEEL PLOW BREAK THROUGH Illinois soil is particularly fertile. It has been described as a “rich black gumbo.” This was a blessing in terms of crop production, but a curse at plowing time. Every few feet the farmer was forced to stop plowing the land and scrape the adhesive soil off the plow before resuming. This added both significant time and labor to the task, especially in the early spring (44). As a blacksmith, both making and repairing plows, John Deere was acutely aware of the problem. Sometime in 1837 John found a broken steel saw for cutting logs on the floor of the Andrus sawmill. Obtaining the saw blade he took it back to his blacksmith shop and converted the smooth steel into the parts of the plow most likely to stick in the soil. Upon testing it was found that this plow would scour. According to Microsoft Bookshelf, 1996 – 1997 edition of The People’s Chronology: “Agriculture, 1837 A self-polishing steel plow fashioned by Vermont-born blacksmith John Deere, 32, at Grand Detour, Ill., can break the heavy sod of the Illinois and Iowa prairie. Deere chisels the teeth off a discarded circular saw blade of Sheffield steel, creates a plow with the proper moldboard curve for breaking the sod, and saves farmers from having to pull their plows out of furrows for repeated cleaning with wooden paddles. The Deere plow will permit efficient farming in vast areas that have defied earlier efforts (see 1839).” By John Deere’s own reckoning, he made 1 steel plow in 1837, 2 in 1838, 10 in 1839, 40 in 1840, 75 in 1841, and 100 in 1842 (50). The John Deere plow was beginning its diffusion process, although as late as 1842 documents indicate he was still considered the town blacksmith rather than as the plow manufacturer (53). Diffusion of the steel plow and other new agricultural tools was slowed to some extent by a widespread belief held at the time that iron and steel could damage the land when it came into contact with it, making the land impure (Hofstadter, Miller and Aaron, 1964). In the end, the plow saved so much time, labor, and back breaking effort this objection was overcome. In 1843 a partnership dedicated to plow manufacturing was formed as Deere and Andrus. This company became Deere, Andrus & Payne in 1844 followed by Andrus, Deere & Lanthrop in 1846 and then evolved into Andrus & Deere in 1847. These organizational changes appear to be largely financial and are apparently based on two factors: the infusion of additional capital or materials and the growing distrust of Andrus by Deere. The personal papers of John Gould, a close associate, suggest that Deere did not understand bookkeeping very well and may have suspected that Andrus was not always forthcoming in his explanations of money flows (70). In 1846 most of these issues were solved by the entry of Francis Deere (aged 18) to the firm, in the role of bookkeeper. Sadly, Francis lived for only two more years dying suddenly and from unknown causes on January 13, 1848. This galvanized John Deere into dissolving the partnership and moving out of Grand Detour to Moline, Illinois. The move away from Grand Detour was probably related to Francis’ death and the earlier business difficulties with Andrus. The selection of Moline appeared to be based on business issues such as better transportation, available labor, available resources, and some clever community marketing on the part of a few Moline residents. In 1848 Andrus & Deere was dissolved in Grand Detour and Deere & Tate was created in Moline. From July to September a plow manufacturing plant was built in Moline and 10 plows had been manufactured by September 26 (75). The weakness of the new Deere & Tate partnership soon became apparent. Both of the men were skilled at production and neither had much knowledge of marketing or bookkeeping (John and Charles were both naturally skilled in marketing, but this was not clear until later in the company history). On a series of trips back to Moline to visit his family, John Deere gradually convinced John Gould, a friend from Grand Detour and a partner in a retail store there, to become a third partner and take over the financial operations of the firm. The addition of a skilled financial executive was so important to the firm that Gould, a full partner, was asked to provide very little capital with the largest portion of that capital lent to Gould by Deere at approximately half the currently going interest rate. Gould’s first two acts justified Deere’s confidence. First, he reviewed, updated, and corrected the Deere & Tate books which were still intermingled with those of Andrus & Deere’s books. Part of the dissolution had involved more than $8,000 of accounts receivable that moved from Deere & Andrus to Deere & Tate. Having caught up the accounts, Gould proceeded to adopt an innovative and somewhat mysterious business practice for the Illinois frontier. He developed a double entry system of bookkeeping for Deere & Tate. As Gould said: “It was well known that Deere and Tate had a double entry system of bookkeeping, which seemed to be a curiosity to the other merchants and businessmen. They frequently came into the office to see the system.” (81) The firm became Deere, Tate & Gould and returned its attention to production, adding new machinery in 1849 which allowed total production for the year to increase to 2,136 plows. By February, 1850 three hundred forty seven plows were being produced a month. Having solved the basic accounting and production issues of plow manufacturing the firm began to focus on marketing. None of the partners knew much about it, but John Deere & Company was destined to become one of the most sophisticated marketing operations in the country. There were two basic issues which drew the attention of the partners to marketing. As the firm’s sales force (known initially as guerrillas, softened to drummers, and finally to travelers) moved into Iowa the first issue emerged. The channel of distribution (made up of farm implement dealers and general stores) was resistant to taking on a new brand of unknown plow. The farmers were also skeptical, especially when the dealers were not advocating the Deere plows. This situation forced the second problem which would soon prove very costly to the company. To get more dealers to take on the plow Deere & Tate allowed the dealers to stock on consignment. Numerous orders for Deere plows read “payment due when sold.” Even a sale to a farmer was not a guarantee of payment by a dealer because many dealers sold to farmers on credit. It was not unusual for a dealer to pay part of his total outstanding bill to a plow manufacturer as the farmers gradually paid the dealer. As stated by Gould dealers would tell the company: “We cannot afford to advance the money. We have sold them to the farmers and got notes…you can wait until we collect.” (87) Gould reported the personal cost of this situation to himself: “Many nights I have gotten out of bed and walked the floor knowing that I had some money to pay in a few days and did not know where I could get it. My brain felt as though I had a swarm of bees in it.” (87) Farm implement manufacturers were forced throughout the frontier to supply their products, through dealers, to farms on credit. This worked in a strong economy, although it was not a perfect solution as can be seen by Gould’s comments. Another marketing uncontrollable was the inadequate transportation system. The Mississippi and its tributaries were the center of the entire system. The “travelers” would voyage by any means possible. Most often they would begin at the river and then spread out by buggy to visit and sell to the farm implements dealers. The plows sold in this way were loaded onto steamboats at Moline and off- loaded near their final destination by teamsters. The teamsters would make their deliveries to the farm implement dealers, then they would take any surplus and sell door-to-door to the farmers. This caused some territory disputes with both the dealers and the travelers, but no serious issues seem to have arisen. The flaw in the system was its dependence on good weather. The rivers froze. The roads became impassible in spring mud. Sometimes this also occurred in fall and summer with apparently impassible mud in wet weather and choking dust in dry weather. Finally, in 1854 the first train made it to Rock Island, Illinois from Chicago. By 1856 the Chicago and Rock Island Railroad had thrown a bridge across the Mississippi (to the enmity of the ferry operators) (89). Although the transportation problems were far from solved, dramatic progress was being made. Communications also began to slowly improve. By 1853 there were direct telegraph lines from Chicago through Rock Island and Moline to St. Louis. (But not at Grand Detour. It is likely that the selection of Moline as the Deere & Tate site was largely driven by John Deere’s ability to project the location of the telegraph and railroad developments near Moline.) Financial issues caused a short-lived crisis for Deere, Tate & Gould in 1850. Start-up costs had eliminated much of the partnership’s capital. Granting credit to dealers limited incoming revenues. In addition, reliable money was in very short supply. Lurking in the background was John Deere’s general inability to grasp monetary issues. (Gould had to correct John’s personal and business finances on occasion.) At this moment in time the partnership was in a very low cash position and the visit from “the credit man” of Lyon, Shorbe, & Company was a serious problem. Deere, Tate & Gould owed them several thousand dollars, apparently for iron and steel. The credit man asked to see the partnership’s private books, to which Gould acceded. After examining the books he looked at Gould and said: “Mr Gould, I don’t see why you cannot pay your debts.” Deere, Tate & Gould owed fairly large amounts to two other companies and if any one of them demanded payment the other two probably would as well. This would have ended the business. After considerable discussion between the three partners and some negotiation with Lyon, Shorbe, & Company, the latter settled for some fairly large chattel mortgages at 6% on the land and buildings of Deere, Tate & Gould. This caused some hard times until August of 1853 (99). Beginning in 1851, perhaps due partly to the financial stress, the partners began to be dissatisfied with the partnership. Another cause of stress worth mentioning was a difference in philosophy between Deere and Tate. Apparently, John Deere was always trying to improve the product line, trying new techniques and adopting new innovations. Tate, on the other hand, thought the farmers should take the products as they were. After all, it was one of the better manufactured line of farm implements available. The partnership became untenable. It was terminated sometime in 1851 or 1852. Gould spent from April to November of 1852 traveling the country, collecting and closing out the business. In March, 1852 John Deere ran an advertisement under the name John Deere as “successor to Deere, Tate, and Gould.” In 1854 Charles Deere joined the firm. Charles began his career as a bookkeeper and as a member of “…a rather easygoing force” (104). After a time, however, he began to attend more closely to business. Once he became familiar with the financial aspects of the business he was moved to sales, often demonstrating the equipment to customers in the fields himself. He was soon advanced to head of sales. During this early period of Charles’ training the new John Deere company prospered. Plows produced jumped from 4,000 in 1852 to 8,000 in 1855, between 13,400 to 15,000 in 1856, and 13,400 in 1857 (105). The number of employees grew from twenty to sixty eight. Internal documents are lacking, but a newspaper reported John Deere sales from March 1852 to March 1853 as $88,000 and in the neighborhood of $140,000 in 1856 (124). Sales were one thing, but collections began to lag and an economic downturn called the Panic of 1857 began to grip the nation. Before turning to the Panic, however, it is important to present the promotion mix methodology which was initially developed by John Deere and refined by Charles throughout his tenure as company chief executive. PROMOTIONAL STRATEGY The years 1848 – 1857 were called “The Golden Age” by some, especially the press. Although the company’s financial crisis of 1850 caused some problems, The Golden Age was a time of important growth and sustained prosperity for the new John Deere company. Several factors lead to this consistent expansion. The background economy, that all-important marketing uncontrollable, slid from moderate growth to strong growth. Prices for agricultural products increased steadily. Farmers began to look for (and were able to afford) improved agricultural implements. With some experimentation John Deere, “successor to Deere, Tate & Gould,” was able to present a promotional strategy that made the Deere plow one of the most sought-after in the industry. Over time, the elements of this strategy became the promotion mix used by both John and Charles Deere. PERSONAL SELLING One of the basic sales techniques of the company was the sales demonstration. This served two purposes. First, it showed the capabilities of the plow when it was used by an expert. Second, it provided the company with valuable information for product improvement. As the farmers discussed the plow with John, Charles, and the travelers the Deere representatives were able to evaluate and incorporate new ideas and needs into their product line. Charles reported:“I used to accompany our wagons in delivering plows through the country and learned to be quite proficient in hitching to and running a plow. Driving horses came naturally to me, whether a plow team or a trotter, and this has always been one of my most pleasant recreations.” (105) The product demonstration appears to have been associated with the earliest beginnings of the company. One of the two extant versions involving the sale of the very first plow has John Deere plowing the first furrow on Lewis Crandall’s land (described as gumbo suprema) to see how well his plow would work (45). Various accounts put John Deere, the travelers, and Charles Deere behind plows working out problems and product innovations with farmers. This technique evolved into using the demonstration to win awards for the company plows and seeders at fairs and competitions. The Deere archives have a photo of Charles Deere in 1905 (aged around 67 or 68) demonstrating the techniques of driving a walking plow (306). SALES PROMOTION, PUBLIC RELATIONS, AND PUBLICITY The medieval fair was probably the origin of today’s sales promotion device known as the trade show. In agriculture during the middle 1800’s the trade show most often took the form of the city, county, or state fair. Farm implements were shown at these fairs as competitions between specific companies’ products were developed. This opportunity was not overlooked by John and Charles. In 1853 the John Deere company won a two dollar prize for the best center draft plow at the First Annual Rock Island County Fair. By 1855 the John Deere company was competing in Iowa fairs as well. The company won both a first and second place for cultivators at the Iowa State Fair of 1855. Part of the competition was to run the plows of different manufacturers against one another over the same ground. In one such competition the John Deere subsoil plow won first prize at the Illinois State Fair of 1855. The Chicago Tribune reported that the Deere plow was the finest the writer had ever seen. These victories accomplished three things. First, they backed up the basic advertising claim that John Deere had been making for years on behalf of his plows. Second, they provided copy for future advertising. Most important, they provided publicity and source credibility – – independent confirmation of the advertising claims from high credibility sources. Numerous magazines and newspapers of the day reported local and state-wide results of the competitions in the fairs. These competitions continued throughout the Charles Deere years, culminating in the Paris Exhibition of 1878 at Petit-Bourg, France (202). The Deere entry, a riding gang plow, won the competition handily. This resulted in advertising copy, but also in a laudatory article in the September 21, 1878 issue of Scientific American, a significant publicity coup. The Gilpin sulky plow, patented in 1875, was a single blade riding plow and won prizes in local, state, and international fairs also It was an enormously popular Deere product. It too performed in the Paris Exhibition and its prizes provided fodder for numerous advertisements. Charles Deere also utilized catalogs as a method of marketing the company product line. The term “catalog” seems to have included several different kinds of promotion including a product line catalog aimed primarily at dealers, separate catalogs targeting farmers, pamphlets directed to promoting one or two specific products, and other kinds of communication aimed at branch houses, dealers, travelers, and customers. Another sales promotion device was a useful booklet circa 1879 measuring 3 inches by 6 inches. It was called the Farmer’s Pocket Companion and contained some farm-related business laws, weights and measurers, postal regulations, a notes and memos section, two pages to record bookkeeping notes on “owed” and “receivables,” and twenty pages of advertising both front and back covered with illustrations of Deere products and testimonials from loyal farmers. A copy of the Pocket Companion can be found in the closed reference section of the Chicago Historical Society. During Charles’ tenure as managing executive the company also used newspaper interviews with Charles as a public relations method of enhancing the firm’s public image. These interviews were used to explain the Deere position on the Grange, on company labor problems, on the “plow trust” and on the proposed buy-out of John Deere, Inc. towards the end of the century. The skillful use of these interviews allowed Charles to present his views in support of the company’s policies. ADVERTISING John Deere used advertising to promote his plows as soon as he could afford to do so. Throughout the John and Charles Deere years the advertising often appeared to be written by the principals themselves, although the art work was not. The earliest advertisements that included art work probably used the art work of plows manufactured by competing companies. (114) The advertisements became increasingly sophisticated with respect to art work and with respect to the product line advertised. The basic advertising theme or creative platform, once established, appeared throughout both John and Charles’ tenure. The Deere advertisement would make a company identification appeal: Deere & Andrus, Andrus & Deere, Deere & Take, John Deere, John Deere & Company, and so forth. The trademark would be presented, if one was being used at the time. For many years the trademark was “The Moline Plow.” Sometimes the trademark appeared on the product itself, sometimes it was presented next to the product’s art work. The product advertised would be presented in a line drawing. A quality claim would accompany the product line drawing. Quality claims were primarily of three types: a prize claim from a fair would accompany the copy, or a product improvement claim would be made, or the copy would extol the popularity of the product with farmers. Some advertisements skipped the art work altogether and concentrated on information advertising, describing the product line (usually within a single product class, such as plows) in detail. Some advertisements touted the interchangeability of John Deere product parts, making repairs easier. Some advertisements also included warranties of various kinds, including warranties that the repair parts would interchange with the basic piece of machinery. It was unclear from the advertisements whether a basic product warranty or guarantee of satisfaction was offered. Apparently because the company name changed so often in the early years after the move to Moline, the company officers selected “The Moline Plow” or “The Moline Plow Works” as the basic trademark until it was determined in court that they would not be allowed to have exclusive use of these phrases. The quality of the product coupled with the advertising and the successes at the fairs established the John Deere product line. John Deere stated in one Deere & Company advertisement that the “IMPROVED CAST STEEL CLIPPER PLOW” was so good that it was acknowledged by farmers to be “…the very best plow in use. We challenge the world to make a better one!” It was probably Deere’s ability to mix promotional communications and to deliverhis quality message convincingly that set the company apart from its competitors, as other manufacturers could usually duplicate the quality of the product. THE PANIC OF 1857 Unlike the Panic of 1837, which had little effect on western Illinois, the Panic of 1857 was devastating to many in the area. Ironically, from the Deere point of view, its underlying cause was over-investment in U.S. production facilities and manufacturing (Hofstadter, Miller and Aaron, 1964). By 1857 more than a billion dollars had been invested in production capital nation-wide. Another billion had been pumped into railroads. A large percentage of the investments were speculative. While earlier panics had been a result of over speculation in land values, the new panic was largely caused by token down payments made on manufacturing and rail securities. Even these minimal down payments were often obtained by borrowing high interest loans from large eastern banks. These banks also acted as the bankers to the country banks, so much so that 70% of the country’s bank reserves were deposited in New York banks alone. In times of financial need, the country banks called in their deposits from the eastern banks. The eastern banks then required payment on the speculation loans. If the speculators failed to pay, the big banks, followed by the country banks, followed by the businessmen, followed by the farmers were pushed to the wall (Hofstadter, Miller and Aaron, 1964). On August 24, 1857 the largest bank in Ohio was forced to close its doors after finding most of its money had been embezzled by its treasurer. Its parent bank then failed. This caused a run on the New York banks which began to close. The failures left the country creditor banks nearly insolvent (Hofstadter, Miller and Aaron, 1964). The farm implement manufacturers, financed by the easy credit in the first place, found their own loans being called in and discovered themselves unable to collect their accounts from either their dealers or the farmers (who, in turn, could not get their money out of their own banks, assuming they had any money in the banks). In September, in an attempt to alleviate some of the cash shortages, investors shipped three tons of gold from California to the east coast on the steamship S.S. Central America. The ship foundered in a hurricane 200 miles east of Charleston losing 420 of 600 passengers and crew. The gold was also lost, increasing the nation’s financial crisis (The People’s Chronology, 1996). “A frequent aftermath of the financial panic, which refers only to the violent stage of a financial debacle, is the decline in real output that ensues as business firms, banks, and consumers attempt to retrench. Loans are made with greater caution, spending declines, unemployment increases, and general economic depression follows.” (Grolier, 1992) The John Deere company was not exempt from these economic uncontrollables. In particular, the company owed large sums of money to the steel suppliers Singer, Hartman in Pittsburgh and Naylor & Co. in England. While the debts would not have been of serious concern in a good economy, the situation became threatening enough for the Deere company lawyer to recommend a change in business organization. Effective July 1, 1857 John Deere became John Deere & Company with four partners: John, Charles, Luke Hemenway and David Bugbee. The partnership had a capital stock of $32,000 with each partner sharing equally. Bugbee apparently plowed $6,178 of capital into the company, for which he received a mortgage (126). More financial stratagems accompanied these developments, perhaps the most significant of which was that Charles Deere purchased a quarter of the plow shop for $10,000 and John and Charles jointly sold the real estate on which the factory was built to the new partnership for $35,000 for a series of notes coming due at different times over the next five years. Broehl (1984) suggests two primary reasons for these maneuvers: First, the agreements put some of the assets in the personal names of the Deere family and moved more assets out of the partnership and into family hands over a period of time, protecting them against personal bankruptcy in the event the business failed. Second, and Broehl views this as the most important, the agreements appear to remove John Deere from principal manager of the company and put Charles in that role (126). Within eight months the financial crisis appeared to be over. Although it was a short period of time it determined the ultimate survival of the company. The partnership was dissolved in March, 1858 and the company returned to its original legal position of July, 1857. Charles noted: “The business fell back into no Deere’s hands.” (128). One would normally assume that, with the return of ownership, management and control would also have fallen back into John Deere’s hands, as well. Broehl (1984), however, argues determinedly that control had permanently passed to Charles (129). Still, Charles was barely twenty one, and not so long ago (in his own words), an “easygoing force.” Two more evolutions of the company organization soon developed. In December of 1858 the company added Christopher Webber as a partner. Webber’s role was unclear and he was not kindly portrayed by the financial agency destined to become Dun and Bradstreet: “…his reputation as a bus. man is decidedly bad, for tho he may be responsible, he is not prompt to pay – but prompt to collect.” (132) That description could, however, have described a number of reasonably good businessmen during the period. John Deere himself was, for the first time, discussed unfavorably in the same publication (135). Both John Deere and Christopher Webber seemed to hang over the company as a threat to its continued survival. Webber was out by 1860 and one would conclude that Charles was definitely managing the company as its chief executive by 1860 at the very latest, except that another financial maneuver of 1864 confounds the issue once more. In July, 1864 the company was again reorganized as Deere & Company. John and Charles shared equally in the business, both contributing $70,000 in stock, buildings, and machinery. According to Broehl: “It was a simple, one-page partnership agreement and the realities of the operating situation were little changed from that of the 1858 takeover by the son.” (150) Yet John Deere became President when the company incorporated in 1868, and remained so until his death in 1886. A public relations brochure printed and distributed by John Deere & Company, Inc. in 1963 and available at the Chicago Historical Society implied that John was the chief executive of the company until his death. Although the exact date that Charles took over the company is ultimately unresolvable, it is important to lay the facts out and to try, because whoever ran the company between 1857 and 1864 is the executive that deserves the credit for the recovery, and probably the survival, of John Deere & Company. Three facts were available to suggest that Charles was really that executive. The first was a report by John Gould some years later in which Gould said that John Deere was out financially although “…he has always given his personal attention to the establishment, and has been about the works.” (129). The second fact was also a personal remembrance by Stephen H. Velie, one of John Deere’s sons-in-law: “The commercial convolution of 1857 came very near to bankrupting him [John Deere] and the management of the business was in 1858 turned over to his son Chas. H. Deere, then 21 years old, who has ever since been acknowledged head of the concern.” (129) A third fact came from the social environment, another marketing uncontrollable. A generation gap of business philosophy existed at that time, according to Hofstadter, Miller, and Aaron (1964). An industrialist of this period hoped to carry the business load only long enough to pass it on to sons or sons-in-law and then turn his own attention to philanthropy or civic affairs. Those sons were businessmen “with the future on their side.” They were corporation executives who looked for profits to come (unlike the previous generation), not from invention or speculation, but from: “…strict attention to management, from cautious financing, careful bookkeeping enhancement of labor productivity, adaptability to changing markets.” (Hofstadter, Miler, and Aaron, 1964 p. 560). These philosophical differences describe the actual behavior of John and Charles Deere beginning sometime between 1857 and 1860. These differences are almost perfectly descriptive of their future lives. John Deere began his public life during this period, becoming a well known abolitionist, philanthropist and civic leader. Charles, on the other hand, showed on numerous occasions the “strict attention to management” of the careful corporate executive, also beginning during this time period. These facts together suggest that Charles’ ascension was not later than 1860, and probably, as Broehl argues, two to three years earlier. Nevertheless, John was definitely “about the works.” For example, he obtained two patents on his own inventions in 1864 and another in 1865. PRODUCTS AND PRICES Over time the John Deere product line became extensive. Both John and Charles were looking for improvements and new products, as evidenced by the patents and expanding product lines. Expansion also occurred regularly within product categories. On many occasions an improvement made in Deere’s shop lead to the obsolescence of previous Deere product lines. Extensive records are lacking, however, and only glimpses of the product lines and pricing are available. Sales were $88,000 in 1853 jumping to $140,000 by 1856. In 1868 – 1869, the first year of incorporation, 41,133 plows, harrows, and cultivators were sold for gross sales of $646,563. Net profit on this revenue was $198,437 (162). Aggregate sales were $710,640 in 1869 – 1870, dipping to a low of $548,605 in 1870 – 1871. From this time sales climbed steadily to $1,167,849 in 1874 – 1875 (793). Sales stayed above a million dollars from that point on, gradually growing to $2,144,570 in 1899 – 1900 which is the latest figure available to us during the Charles Deere years. Profits did not always follow sales directly. They climbed steadily, however, from a low of $28,130 in 1872 – 1873 (previous years had higher profits) to $511,711 in 1898 – 99. (797) (Sales and profits continued to climb after Charles. In 1914, for example, profits of $2,085,000 against sales of $29,000,000 were recorded.) (798) The product line has to be sketched based on occasional company records and advertisements. In 1853 – 1854 an internal document records plows described as two horse steel landslides [sic] at $11.00 retail and $8.00 wholesale and plows that were two horse iron landslides [sic] at $10.00 retail or $7.25 wholesale. A “B” or twelve inch plow was listed at $6.50 cash or $7.00 when paid in full by October 1 (wholesale) or $9.00 retail with “10% added” when paid in full by October 1. The “C” plow was a ten inch plow and retailed for $8.00 and wholesaled at $6.00 on the same terms for cash or partial credit. Breakers were plows that could cut through “the heavily matted, grass-rooted, virgin soil,” and allow the first shallow furrows to be planted. Once a field (or furrow) was broken, less powerful plows could be used in future seasons. Sometimes farmers had to hire a team of “breakers,” men driving eight to twelve oxen using breaker plows (Hofstadter, Miller, and Aaron 1964). In the 1853 – 1854 product list John Deere sold breakers for $15.00 (cash only) and “Extra rigging for breakers full” at $10.00 (106). An advertisement for “Moline Plows,” most of them called “Clippers,” of around 1857 listed eight variations on plows being sold. The differences were based on the size of the cut (14 inches or 12 inches), whether the mold board was made of German Steel or American Steel, and the designs of the plows which were specialized for different tasks. One plow was, for example, “…universally esteemed for plowing in heavy stubble.” While another was for “…old ground plowing.” The twelve inch plows were “…got up to meet the objection sometimes made that the 14 inch clippers were too large for an ordinary team;” this last is classic Deere product improvement and advertising technique (107). More improvements were made in plows and other agricultural machinery during the Civil War. Farmers who opened new farms in the 1840s and 1850s typically started with a farm of forty acres. With the improved machinery farms of sixty to seventy acres of crops became common. However, the investment in farm machinery jumped from $10 to $20 dollars in the 1840s to $120 in the 1860s. Charles continued the tradition of product improvement and product line expansion during this period. In 1860, for example, he expanded the catalog to thirty pages from twenty four pages in 1859. (140) One of his earliest notes was to investigate a Corn Sheller made in Chicago (134). In 1864 the company and the product line got a significant long-term boost when Gilpin Moore came to work for the company. Moore’s best known invention, a riding plow called the Gilpin Sulky, became a mainstay of the John Deere, Inc. product mix. By the time he retired in the 1890s, Gilpin Moore held thirty one patents in his own name and four other patents with shared ownership. John Deere obtained the firm’s first two patents in 1864 relating to the casting of the steel plow. In 1865 he obtained a much more complicated patent with a methodology for securing the parts of a plow so they were held together more firmly, but at the same time had a more detachable assembly. (149) In 1863 the company added a new product line, the Hawkeye riding cultivator used to loosen the soil and destroy weeds. This was the first riding product in the Deere product mix. The Hawkeye was considered a major innovation and won the first premium at the Iowa State Fair of 1863. (149) Five hundred Hawkeyes were sold in 1864. More than 2,000 were sold in 1865. (150) The primary Deere products in the second half of the Nineteenth century fell into five classes. The first was plows, including walking or wheeled plows which came as either single bottom (cut) or as gang plows. A second product line was cultivators, also either walking or wheeled. Harrows, defined below, were a third product line. Harrow – A farm implement consisting of a heavy frame with sharp teeth or upright disks, used to break up and even off plowed ground. The fourth product line was drills and planters. The fifth consisted of a variety of wagons and buggies. In the 1890s bicycles were added. (200) Charles Deere continued in the tradition of his father, constantly looking for new improvements for all of the product lines. For example, in 1881 the Gilpin Sulky Plow was greatly improved by a device called a “power lift” that allowed the farmer to pull the plow from the soil after one revolution by putting hand pressure on a catch. (203) John Deere & Company, Inc. offered to add this feature to the older Gilpins. The gang plow was improved in 1884 and 1885 by the addition of a level that allowed the farmer to vary the depth of the plow while the plow was still running. (206) Both John Deere in the late 1850s and Charles Deere in the early 1890s attempted to put together a steam engine and a large gang plow to create a steam plow. (120, 206) Steam engines applied to agricultural equipment failed to develop into successful products, however. Also in the John Deere tradition, Charles was quick to utilize improvements made by other manufacturers. One example was the three wheeled gang plow (The Deere New Deal Gang borrowed from the Moline Plow Company’s Flying Dutchman). Another example was the staggered wheel model of the gang plow introduced by the Oliver Chilled Plow Works adapted for the Deere Gazelle Plow. (205 – 206) In 1877 Charles Deere and Alvah Mansur formed a separate corporation to manufacture corn planters. This rotary drop machine saved significant time and effort in planting corn. (213) The company’s first year profits were $10,000 and were $48,000 in 1882. (212) Additional labor saving planters were developed and placed on the market in 1881. In 1879 Deere & Mansur introduced a stalk cutter and in 1885 a sulky hay rake. According to a company historian, the reason Deere & Mansur was kept completely separate from John Deere, Inc. was so that only one major farm implement would be manufactured by any one plant. John Deere, Inc.’s major implement was, of course, the plow, while the planter was the major implement of Deere & Mansur. (218) Another company that began as a separate entity was The Moline Wagon Company which supplied many of the wagons sold by Deere. This company was eventually bought out by John Deere, Inc. in the early 1900s. Deere & Webber, one of the “branch houses,” began the bicycle business at John Deere & Company, Inc. By 1894 Deere and Webber had ordered 1,000 bicycles for resale. By 1895 the branch house was having three brands of bicycles manufactured under the Deere name. (225) Both John and Charles Deere showed considerable skill in developing new products and improving old ones. In addition, both men were able to market and sell, and had an innate understanding of the marketing concept in the century preceding its development. John was probably not a great inventor in the Thomas A. Edison sense of invention and Charles was apparently not interested in that aspect of his company. However, Charles innovation of the branch house form of distribution channel was his own invention, based on his understanding of marketing organization, his product line, and the value of personal incentive. It probably could not have been duplicated by his father. CHANNELS OF DISTRIBUTION Even the original John Deere plows were technologically advanced enough to require some demonstration. As John Deere & Company, Inc. moved farther into the Nineteenth Century the agricultural machines became more and more complex, and more specialized. The new machines required professional demonstrations, complex and expert servicing, and continuing post sale follow-up. (175) General stores, often distributors of the original John Deere plow, gradually dropped out of the distribution channel. Most of the machine companies of the period solved the problems of complexity, specialization, service, and follow-up by setting up company owned branch stores. Broehl (1984) cites International Harvester, I.M. Singer sewing machines, E & T Fairbanks, the scale company, and typewriter manufacturers as examples of the wholly owned branch operation. (175) Charles Deere, however, invented his own system of branch organization which had some very positive benefits throughout the distribution channel. The Deere method of branch organization was a partnership, which Broehl calls the manager operated branch house. The first of these organizations was made up of executives of John Deere, Inc. acting in a partnership independent of John Deere, Inc. with Alvah Mansur in Kansas City in 1869. This form of distributorship worked well enough that its basic form was copied in other cities by Charles Deere between 1869 and 1889. The cities included St. Louis, Council Bluffs, Minneapolis, and San Francisco. Mansur retained his partnership in the Kansas City branch and moved to St. Louis in 1875 and set up a second branch house with Charles Deere there. In each of these cases resident managers were hired and given part of the profits. (182) In Minneapolis one of the John Deere, Inc. distributors, W. J. Dean, began the branch house in partnership with Charles Deere and C.C. Webber (the son of the John Deere partner of the late 1850s derided by the precursor firm of Dun & Bradstreet). Stephen Velie, a John Deere, Inc. executive soon joined a reorganized partnership. The partners in the Council Bluffs branch house started in 1881 included John Deere, Charles Deere, and Stephen Velie from John Deere & Company, Inc. for a one third share. Another third share was taken by The Moline Wagon Company. A final third was acquired by the branch manager, Lucius Wells. The partnership went by the name of Deere, Wells, & Company. In California the original branch organization was again made up of a distributor (Marcus C. Hawley & Co.), Charles Deere, and the manager Frederick Vaughan. Unlike the other branches, the California house was incorporated. This branch was to prove troublesome, but the pattern of the branch house worked over time even there. The purpose of the branch houses was to make the marketing organization more responsive. The rest of the company remained centralized, but marketing had grown too big for the needs of the numerous dealers and the vast numbers of customers. (177) The branches provided a mostly autonomous management of their respective territories. Because of their organization they brought invaluable individualistic styles, views, and contributions to the Moline power base. The strength of the semi-independent branches was also something of a trial. Because of the branches’ independence the regional and local needs of the customers, both farmers and distributors, were much more likely to be met. At the same time, channel conflict between the centralized manufacturing and financing operation and the branches was certain to emerge, which it did. Because of the mutually shared ownership interest between the far-flung branches and the Moline-based executives very careful thought to resolve the conflicts was (usually) ensured. Because they were partners in the branches it was in the best interest of the Moline executives to look at any issues raised by the branch houses from the branch perspective, as well as from the needs of the central office. The branch organization developed by Charles had other advantages as well. First, the basic goal of decentralization from Moline was met, that of better communication with the distributors and customers through the branch houses. Also, because the managers were rewarded based on profitability their personal incentive was enlarged. This was not a typical arrangement at this point in business history. Another strength of the branch houses was the fulfillment of the transportation and storage function of wholesalers. Large quantities of products could be shipped and stored in advance of sales to the branch houses. New product development was very much controlled by Charles Deere and by Stephen Velie. Nevertheless, a letter from Velie to Deere during one of Charles’ field trips reveals some of the branch influence on the Deere product line: “In the conduct of our business in the past we have, I believe, been more disposed to cater to the wishes of our customers as made known to us through our own traveling men and those of the branch-house than perhaps any of our competitors…with the draw- back however of having to carry a larger stock … possibly carried to excess in some direction.” (186) Velie also acknowledged that the company had “…taken on a larger volume of business than we otherwise would have done.” as a result of listening to the travelers and the branch houses. Branch house pricing and pricing to retail distributors both became problems that had to have constant attention. First, the dealers, even though getting the same price from the branch house or from Moline, were quite competitive and were somewhat suspicious that other dealers might be getting a better price. When the dealers cut prices against one another they demanded lower prices from the branch houses. The branch houses themselves were often working on John Deere & Company, Inc. to increase their discounts. Because the product line was so large and the depth of many of the lines was extensive price reductions for specific models were often possible. When one branch was able to get a special price, however, the news quickly spread to the other branches who would then often demand the same price. Warranties, repairs and other costs faced by the branches were probably made more complicated than in a centrally owned organization as the branches negotiated each of these issues with Moline. The end result was, however, a company that was much more responsive to local conditions and much more careful of its markets that would otherwise have been the case. Territorial rights were also a problem between the branches. No specific territory lines had been drawn in the partnership agreements and so some disputes over territory were guaranteed to occur. In addition, some individual dealers refused to go through the branch houses and ignored any attempts at territorial restrictions. Even with the problems associated with the semi-independent branches, the system worked very well from both the profit perspective of the partners and from the point of view of maintaining the John Deere & Company, Inc. market position and share. Long before the marketing concept, Charles Deere developed a channels organization that guaranteed the economies of a wholesaling-like middleman to the channel, but which also ensured customer feedback would be presented to the manufacturing offices of the company in a straightforward and forceful way. This was accomplished at a time when advances in manufacturing and production processes, transportation, and finance were the central concerns of business executives. Just a few years earlier the detection of counterfeit paper money and coins qualified a person as a sophisticated bookkeeper and a blacksmith shop was an adequate start for a production process. THE PLOW TRUST During this period of American history the manufacturing firms and producers were able to grow larger and larger thanks to technological innovation and significant growth in demand as more immigrants moved into the country. But entry into production and manufacturing was still relatively easy and it could be done with fairly small capital reserves. The result was competition and every successful manufacturing industry had a lot of competitors. The plow industry was particularly prone to competition and the natural result was for the companies to try to find a method of consolidating, or a method of fixing prices. In 1864 fifteen plow manufacturers met in Chicago and formed a “plow makers’ society.” By this time Illinois ranked highest in the nation in plow production and fourteen of the manufacturers were Illinois businesses. The topic of the plow makers’ meeting was the manufactures’ concern over rising prices in the iron, steel, and paint and varnish industries. This would increase the over-all production cost per plow around $1.00 each. That was against plow retail prices of eleven to sixteen dollars depending on the type of plow and the manufacturer. The plow makers agreed that they should agree to move prices up together to reflect their increased costs. (150) They recognized that if they continued to compete as vigorously as in the past, a significant profit squeeze was likely to result. On June 30, 1864 the group had a second meeting and created the Northwestern Plow Makers Association. Charles Deere was elected secretary. By December 1864 steel, iron, and paint prices had continued to increase and the Association voted another “moderate” plow price increase. (151) Over a number of years the Northwestern Plow Makers Association operated in this fashion, agreeing on prices, setting warranty policies, and working out other issues. But it was much more a lose confederation of a minority of plow makers, rather than an organization which could dictate or sanction misbehavior (259). In the late 1890s, after the Sherman Act, the Northwestern Plow Makers Association and other manufacturers attempted to combine in order to get more control over the cost pressures of their suppliers and the downward pressures on prices they experienced from their competitors. Charles Deere was reported in the press to be the president of this developing American Plow Company – – which would begin its life with $60,000,000 in capital and was made up of the largest plow manufacturers. (279) However, there was never enough agreement within the industry to put together the series of mergers that would have made the company possible. The two principle causes of the failure were that the prices the manufactures wanted for their companies were excessive and labor unrest about the consolidation too great for the consolidation to work. (286) In 1889 a British group of investors began negotiations to purchase outright Deere & Company, Deere & Mansur (the manufacturing company, not the branch, apparently specific branches were to be purchased by Deere & Company as part of the deal), and their competitor, The Moline Plow Company. This company would have been a powerful organization, the equivalent of a large merger which would hopefully result in some economies of scale. Deere & Company were not able to put the deal together in time enough to suit the British investors because The Moline Plow Company could not agree on a price for their firm with the Deere interests. Deere & Company then attempted to put the deal together without Moline Plow with a different set of investors, but nothing except a large amount of work appears to have come of this venture. (260 – 270) THE GRANGE While the plow manufacturers believed their suppliers wanted too much money and were too well organized for the taste of the plow makers, the farmers felt the same way about their suppliers and the middlemen they faced. The farmers’ suppliers included the plow manufacturers. In December 1867 the Order of Patrons of Husbandry was formed with the purpose of “…social improvement and enlightenment of the agricultural classes.” (162) “The Grange’s” agenda was more specific than the statement of purpose, however. The Grange grew slowly at first but in 1873 another Panic hit the banking industry and in 1874 a grasshopper invasion throughout all Midwestern and Plains states pushed the farmers ever closer to economic ruin. The leaders of The Grange decided to become more militant in support of their membership, and the farmers suddenly found they had a friend in The Grange. After the Civil War farm prices for farm products had declined but the cost of farm machinery had increased. Overextended credit purchasing encouraged by the banks, the farm implement manufacturers, and the farm implement dealers placed the farmer in a hard position in the mid- 1870s. Catering to the needs of its membership, The Grange began to look for targets. The railroads and the coal companies came in for their share of criticism, but agriculture-specific businesses were bound to be singled out the most. The target of greatest opportunity appeared to be the farm implements middleman. If only the middleman, who didn’t actually do anything but add an extra 30% to 50% to the final price of farm equipment, could be removed from the system then farmers could buy directly from the farm implement manufacturers at considerable savings. And, wasn’t it the farm implement manufacturers who had set up the middlemen in the first place? The middleman was a “parasite,” a “dead weight on society,” and “a leach on the purse of the producer.” (164) “The smooth-tongued gentleman who calls on us with his matched grays and fine carriage and persuades us that we need a reaper…must be paid for his visit.“(164) The most expensive farm implement was the reaper and Cyrus McCormick became a much-discussed and abused target. His answer to The Grange was: “When we are approached by…[Grange] agents with propositions for the purchase of our machines for cash on delivery, and in considerable numbers, we shall, of course, be pleased to meet them…to deal directly at our city office, or indirectly through our agents, with farmers or their agents…” (165) In other words, a deal could be made with the farmers or The Grange that would, in effect, include a volume discount for large orders, provided they were for cash. Looking more closely at the detail of what McCormick said the farmers learned that the total price would be the same for a specific volume of reapers whether the farmers dealt with McCormick’s offices in Chicago or his agents in the field. (165) The farmers turned their attention to the plow manufacturers. The Northwest Plow Manufacturers Association met in 1873 to decide how they should respond to the demand for direct sales. They decided they would sell to farmers directly only at retail prices, but that their retailers would be encouraged to sell at rates “much reduced” when the offer was for cash. The farmers were not pleased with this answer from the “Plow Ring” and began to put pressure on the individual manufacturers to break free from the Northwest Plow Manufacturers Association agreement (seven of the twenty eight manufacturers had refused to sign the agreement in the first place). (166) In January of 1874, Charles Deere was interviewed on the issues by the Chicago Tribune. The questions and answers were reported verbatim and they provide some significant information about the man and his views. Charles began by supporting The Grange as it “…was rightly directed and much good will come of it.” (166) However, the farmer was basically the cause of his own problems for two reasons. First, the individual farmer wanted to overproduce to maximize his own sales, which drove prices down because it increased total supply. This caused farmers to want to put more acreage into production, so they bought more land on credit from the banks. More land forced the farmers to buy more farm implements, also on credit. The greatest evil was the credit system “…the abuse of which has involved not only farmers, but others, beyond their present ability to extricate themselves.” (166) During the Civil War good crops and good agricultural prices had made the credit system less necessary, but after the Civil War “… the great competition and the anxiety to sell have led to lengthened credits, by which the farmer has been involved in debt for much that he could more profitably have got along without.” (166) Many farm implement manufacturers were in roughly the same position as before 1857 with respect to overextended credit (but not Deere & Company, Inc. – – not under Charles’ management). The solution to the entire channel’s problem; the farmers’ problem, the farm implement dealers’ problem, and the implement manufacturers’ problem was the adoption of the cash system. (Charles was speaking of an “ideal” system. If credit was what it took to make a sale that had a good chance of payment, Charles had Deere & Company take it.) But, if the cash system were to have been adopted then farmers would take better care of their farm equipment and fewer purchases would be necessary. As to the importance of middlemen, Charles said they were the:“…outgrowth of necessity and have taken their position …with the encouragement of farmers…who prefer to make their selections from stocks kept on hand for their accommodation, just when they have need of a particular implement, and who find it very handy, in case of breakage to go to the same middleman and get the necessary repairs.”(168)In his defense of middlemen Charles reversed himself briefly on the issue of credit sales:”When the poor emigrant has secured a homestead and, with the last vestige of his means, has put up a little shanty, he finds that he needs implements to till the soil. He goes to the middleman, tells him he has nothing left, and asks to be trusted for the things which are indispensable to his success. The middleman has confidence in his honesty, and gives him credit and, with it, a substantial start in life.” (168). Charles can be forgiven for the almost lyrical quality of this presentation when one considers the equally lyrical descriptions of the heroic farmer which were accompanied by vitrolic attacks on the middlemen and manufacturers being made by The Grange and some of the farm publications.Within the less lyrical parts of the interview Deere tells the reporter that John Deere & Company, Inc. will deal directly with farmers, but on the same terms as stated by McCormick. The company had not done so yet because they had to ship in carload lots, which would require a minimum order of 150 plows or 100 cultivators and no Grange organization had yet offered to buy in that quantity. Another interesting fact developed by the reporter in the interview was that Deere & Company, Inc. considered its retail prices to be ceilings. “We have a list price, which is the maximum dealers are allowed to charge. It affords them a fair compensation…and allows them to deduct a percentage when they think it is to their advantage to do so. No restraint is placed upon them in this respect. They are at liberty to sell plows as cheaply as they desire or can afford to. If there were no middleman limit, extortionate charges might be made in isolated localities.” (169) The reactions to the interview were mixed and both farmers and middlemen wrote the Chicago Tribune to present their views. One farmer declared Deere’s arguments “…a very lame affair.” Middlemen, on the other hand, tended to center in on an argument made by Deere and expand it with additional factors that had not been covered to their satisfaction. One pointed out that he carried a number of different plows from different manufacturers, assorting the line, which his customers required him to do, but which added greatly to his costs. A farmer commented that it was all right for Deere to talk about the speedy repairs offered by the middlemen, but his own experience had been that the parts he needed were never in stock. In December 1873 the Illinois Grangers Convention denounced the Northwestern Plow Association’s previous resolution and decided on a boycott. In the process the Grangers attempted to put together their own farm implement companies to supplant the manufacturers. These actions failed, largely because of the inherently disorganized nature of The Grange, as Charles suggested in his interview with the Tribune. It was far too decentralized and locally independent to be able to develop very many efficient manufacturing capabilities. Eventually the granges who attempted to compete with the farm implement manufacturers (and the manufacturers who went along) charged prices too low for survival – – apparently not understanding accounting or overhead costs well. The Grange failed to change the farm implement manufacturers, but in 1990 existed in 37 states with 365,000 members. PERSONAL GLIMPSES Charles Deere fulfilled his business potential for John Deere at just the right time. He was educated for business and had the drive and skills necessary to carry his father’s company through its worst time. John Deere and Company, Inc. today carries his stamp as much as it does John Deere’s. Understanding Charles Deere can be aided by looking at the few glimpses of a personal nature we have. The first view available is during that high pressure period after the Panic of 1857 when Charles was taking responsibility for the business. John Deere and Christopher Webber, both partners in the company to whatever extent was true of that period were hounded by creditors and the company itself was at risk. It was a difficult time for many people and, during a business trip Charles reached a point of great resolution which he followed throughout his life. In a memorandum book he carried with him on business trips he recorded a hard learned lesson: “I will never from this seventh day of February, eighteen hundred sixty A.D. put my name to a paper that I do not expect to pay – so help me God.” Is this as a result of observing his father’s difficulties? Did he have financial problems of his own historians know nothing about? Or had he just witnessed some financial tragedy of a third party? Whatever the case, his future financial management of his company was very effective. A second look at Charles is during the Candee, Swan & Co. court case of 1867 in which Charles may have let his anger get the better of his judgment. Candee, Swan & Co took up manufacturing of plows in Moline in 1866. Their plows were extremely similar to the Deere plows, their trademark could be mistaken for the Deere trademark at ten paces, and by today’s standards, Candee, Swan’s sales representatives were clearly misrepresenting themselves as coming from the Deere manufacturing works, unless they were asked specific, astute questions by the dealers. The Candee, Swan catalog adopted almost identical products, product numbers, and prices. This was too much for Charles and he took to advertising to express himself: “…Another evidence of superiority is found in the fact that plow makers in different parts of the country are changing their styles and shapes to imitate ours, while others go still farther and assert that they have a mechanic from our shop (discharged years ago for incompetency) and are making the ‘Moline Plow,’ advertising them as such, and seeking to get them introduced on the reputation our plows have acquired…” (154) The mechanic was, in fact, Andrew Friberg who had been Deere’s chief superintendent in the past and was certainly not incompetent. Nor was Friberg particularly concerned about the ethics of copying his old firm’s product line. In a later advertisement, Charles went even farther:“…unscrupulous manufacturers have recently appropriated this name for the purpose of palming off a confessedly inferior imitation using all the numbers, letter, names peculiar to our plow. We really believe that no man can live an exemplary Christian life and use a poor plow…” (154) Eventually this matter went to the Illinois Supreme Court and it did not turn out well for John Deere & Company, Inc. The Court ruled that, while there were some questionable practices, there was no real reason that Deere should have an exclusive right to “The Moline Plow.” Further, the plow manufactures, including Deere, had all borrowed freely from one another’s designs and catalogs in the past. (161) Fortunately, Charles did not take out an advertisement about the Supreme Court. In his dealing with the Chicago Tribune and the Grange Charles shows a very high level of professionalism and skill at communication, in contrast to the advertisements in the Candee, Swan case. Under Charles, the company took an almost paternalistic attitude toward its employees for the late 1800s. The company was responsible towards its employees, developing a benefit program unique for its time. (254) When industrial accidents occurred, as they often did in the Nineteenth Century, “…the company was assiduous in concern and generous in compensation long before it was required by workmen’s compensation laws.” (254) Deere & Company, beginning with John Deere’s selection of Francis Deere, then Charles, his brothers-in-law, then his sons-in-law and grandsons, tended to reach into the family for his top managers. As one business historian put it, this practice is “chancy.” The business skills of an individual are not often evidenced by the selection of a marriage partner. Charles Deere inherited this practice and the family, yet he was able to get the best out of a large variety of individuals within and out of the family. It is possible Charles held on to the company a few years too long. He suffered from pernicious anemia and it drained his energies. (281) In 1903 Webber suggested an Advisory Board which would look into the needs of the company, but which would probably have been used to supersede the “Old Board.” The Advisory Board was voted into existence, and its scope was extensive. But the Advisory Board made contentious recommendations and the Board of Directors met and voted it out of existence. If it was a power play, an attempt to get around senior management or to get more branch office representation into the central office because Charles was perceived as weakening, it failed. (298) Charles Deere was a tough competitor, a good leader, and a business manager who showed himself to be capable in finance, marketing, sales, company organization, new product development, and labor relations. He left his stamp on the company as surely as his John Deere left his. Charles Deere was able to take a financially troubled regional manufacturing firm and bring it through economically bad times, significant technological changes, important social changes, and rapidly advancing business practices so that it was ready for the new challenges of the Twentieth Century – even though Charles himself was educated in the middle of the Nineteenth Century. On October 29, 1907 Charles Deere died in Chicago. He was, of course, on John Deere & Company business. This article was written by John S. Wagle, Ph.D. was a professor of marketing at Northern Illinois University, DeKalb, Illinois 60115 REFERENCES 1. Broehl, Wayne C., John Deere’s Company, A History of Deere & Company and Its Times, Doubleday, New York, 1984. 2. Compton’s Encyclopedia of American History, Compton’s New Media, A Tribune New Media Company, 1994. 3. Hofstadter, Richard, William Miller, and Daniel Aaron, The American Republic, Vol. 1, Prentice-Hall, Englewood Cliffs, 1964. 4. Makers of Plenty, John Deere…the Man and His Company, Deere & Company, 2nd Printing, 1963, p. 926. 5. The American Heritage Dictionary of the English Language, Houghton Mifflin, New York, 3rd. ed. Electronic version licensed from INSO Corporation. 1992 6. The People’s Chronology, Henry Holt & Company, Inc. Copyright 1995, 1996 by James Trager. 7. The Random House Dictionary of the English Language, The Unabridged edition, Jess Stern, ed., Random House, New York, 1967. 8. The Software Toolworks Multimedia Encyclopedia, Grolier, Inc., Online Computer Systems, Inc. 1991, 1992. FOOTNOTES Numbers in parenthesis without reference names are the page numbers associated with notes from Broehl, John Deere’s Company. (See End Notes). The People’s Chronology is licensed from Henry Holt and Company, Inc. Copyright © 1995, 1996 by James Trager. All rights reserved. This appears to refer to company debts rather than personal ones. The partnership had somewhere in the vicinity of $30,000 in credit sales at this time, but very little actual cash. Several plows with moldboards linked together in one efficient plowing machine, in this case a riding plow or a sulky. Makers of Plenty, John Deere…the Man and His Company, 2nd printing, Deere & Company, 1963 p. 926. The Company name is technically Deere & Company, Inc., but often referred to as John Deere & Company. One could also argue that the former is an entrepreneurial philosophy and the latter is a managerial philosophy, both of which are current, somewhat opposing views of business development. Nevertheless, the “generation gap” hypothesis fits the industrial revolution period of John and Charles time better than any other. Almost certainly landsides, “the part of a plow consisting of a sidepiece opposite the moldboard, for guiding the plow and resisting the side pressure caused by the turning of the furrow.” The Random House Dictionary of the English Language, The Unabridged Edition, Jess Stein (ed.), Random House, New York, SV Langton, p. 805. The American Heritage® Dictionary of the English Language, Third Edition copyright © 1992 by Houghton Mifflin Company. Electronic version licensed from INSO Corporation. All rights reserved. John Deere’s son-in-law, John Deere, Inc. Secretary, and probably Charles’ closest confidant in the company In 1860 Illinois had 121 plow manufacturers. (123) An 1874 Wisconsin newspaper editorial, unspecified by Broehl. Chicago Tribune, January 17, 1874 Charles’ point of view comes from the credit debacles that almost ruined John Deere in 1857. It fell largely to Charles to extricate the company from this and throughout his career he was anti-credit. This did not prevent the company from accepting sales on credit, however.Copyright 2001 American National Business Hall of Fame. All Rights Reserved.

Click for Slides related to JOHN DEERE & CHARLES DEERE

Download slideshow related to John & Charles Deere – John Deere & Co.

ANBHF Laureates

Our laureates and fellows exemplify the American tradition of business leadership. The ANBHF has published the biographies of our laureates and fellows.

Some are currently available online and more are added each month.